Signage for Shopping Events: Best of banners, directional signage, posters, and floor graphics to guide shoppers and promote the event.

Acrylic Sheet Price in Bangladesh

Acrylic Sheet Price in Bangladesh in neon | name plate | billboard | glass | sticker | indoor | letter | design | light | wall | outdoor, BD.

SS Acrylic Top Letter LED Sign Board Price in BD

SS Acrylic Top Letter LED Sign Board Price in BD Illuminating your business with LED signage can make a significant difference in attracting customers. In Bangladesh, SS Acrylic Top Letter LED signboards are rising in popularity. They combine modern aesthetics with functionality to showcase your brand beautifully. LED signboards grab attention effortlessly. Their bright lights and vibrant colors make them stand out,

Best LED Signage Agency in Dhaka Bangladesh

Best LED Signage Agency in Dhaka Bangladesh LED signage for business is the best marketing tool to engage the people outside your doors who are most likely to come inside. If you don’t have a digital sign, now is the time to get one and if you have had one for a while, you’re likely looking to upgrade. Before you invest in a new LED sign, you want to make sure you’re getting the best sign on the market, that actually will grow your business.

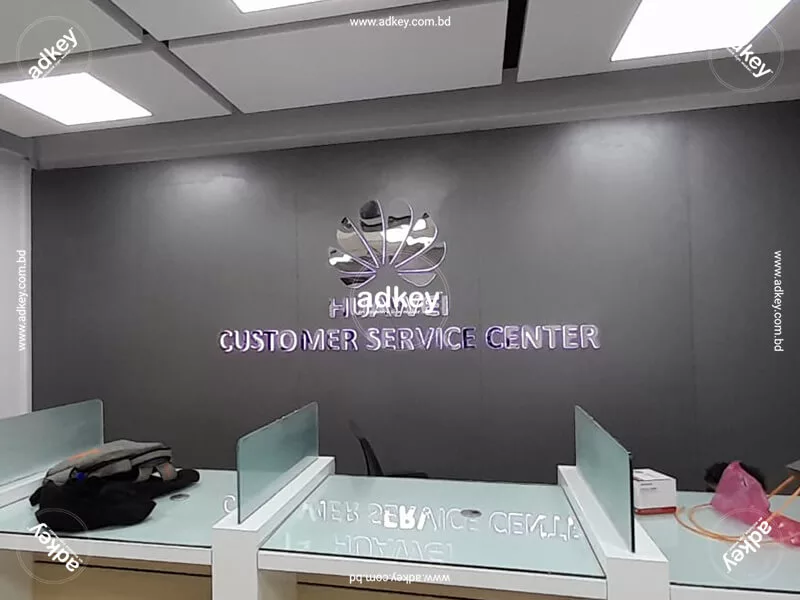

Illuminated Custom Office SS Sign Board Price in BD

Illuminated Custom Office SS Sign Board Price in BD. Brighten your workspace and attract clients. Contact us now for a quote! . Our digital price tags are designed to improve efficiency, accuracy, and customer satisfaction in the retail industry. We offer the most advanced electronic shelf labeling system and complete technical support

LED Sign BD 3D SS Acrylic High Letter LED Module Light

"Explore premium LED Sign BD 3D SS Acrylic High Letter LED Module Light for standout signage solutions. Durable, stylish, and energy-efficient, perfect for businesses in Bangladesh. Competitive pricing and custom designs available.

LED Sign Board BD Acrylic Letter Signage Company 2025

LED Sign Board BD Acrylic Letter Signage Company 2025 LED sign boards with acrylic letter signage have become a cornerstone of modern branding and advertising strategies in Bangladesh. Businesses across industries are leveraging this innovative signage solution to enhance their visibility and create lasting impressions. In this comprehensive guide, we’ll delve into the details of LED sign boards in Bangladesh

Acrylic Sign Letters | Acrylic Letters for Outdoor Signs

Acrylic Sign Letters | Acrylic Letters for Outdoor Signs Acrylic Material Has Certain Chemical Properties That Need to Be Considered

Sign Board BD Neon Sign BD Name Plate LED Display Shop Signs

Sign Board BD Neon Signage is a vital aspect of modern branding and business promotion, and in Bangladesh, businesses are increasingly opting for innovative solutions like neon signs, name plates, and LED display shop signs. These options offer high visibility, aesthetic appeal, and durability, making them a preferred choice for businesses looking to stand out. In this guide